In late 2010, the University of Auckland first considered the feasibility of upgrading its outdated science sector buildings.

The site was chosen for the new building on the corner of Symonds and Wellesley Streets. This building project was fast-tracked with tight deadlines (demolition started in late 2011 and the building was completed early in 2013).

The project was contracted via Aquaheat NZ Ltd, and it went to Express Sheetmetals because of their high-quality manufacturing of ductwork and unique capabilities in Stainless Steel manufacture.

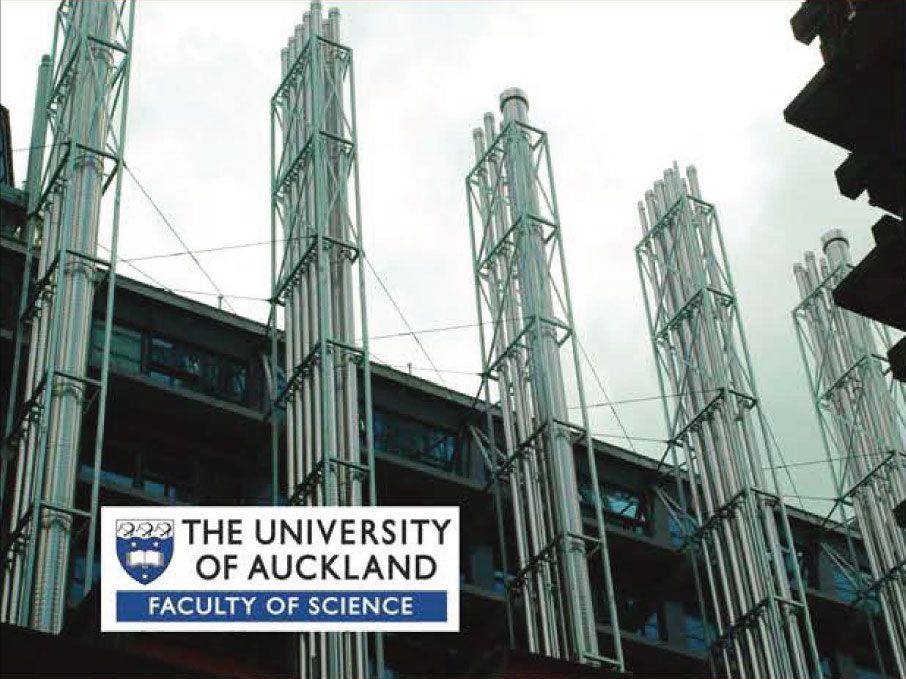

Due to the very tall vent stacks required, the engineering challenge presented was ideal for Express Sheetmetals to showcase their expertise in constructing long pipes with fewer pipe segments.

According to Aquaheat Project Management, "There were 50 stacks in total, a large number by any means."

Why the large number of stacks? Fume cabinets need to be vented separately to avoid incompatible chemicals mixing, making the installation of some ducts extremely complex. Externally, they were stainless steel, spiral, and fully seam-jointed. Express Sheetmetals carried out this job efficiently and professionally.

Particular significance was given to the long lengths of ductwork required for structural integrity- 9 or 12 metre lengths. Fewer joints meant less room for problems with the building structure. Express Sheetmetals has invested heavily in machinery and the latest technology to ensure full custom manufacturing capacity. Express Sheetmetals supplied accordingly, working to very tight supply timeframes.

On closing Aquaheat state: "There were no delays, and they certainly deliver".